Fastest OT installation in record time

Jupiter Hospital has set the record for the fastest installation of Robotic Operation Theatre. As there was a need for an additional Operation Theatre in the Hospital, the management decided to temporarily shut down the OT complex, but this could only be done for a brief period of time, as we could not let our patients suffer. It was decided that the entire work of demolishing the existing isolation rooms, carrying out all MEP work, and constructing a bigger operation theatre which was apt for Robotic Surgeries, would be done during the Diwali Vacation.

On average, it takes about three weeks to Commission a new OT, but, it was not possible to keep the OT complex close for that long. A proper protocol was decided in such a way that the entire commissioning would be completed in a span of 7 days.

The team worked in close coordination, ensuring the right optimization of time and efforts.

- On 22nd October, the Operation Department was handed over to the project team and this marked the beginning of our mission. The passage wall between OT-4 and Robotic Ready OT was demolished. OT-3 and 4 Electrical Transformer was shifted to the service floor and power supply DB was shifted in the passage behind OT-4

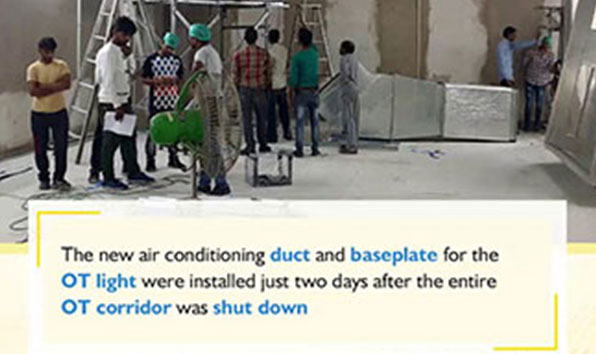

- On 23rd October, Robotic Ready OT wall side panelling was done, and the ceiling painting started. Return air risers were installed and HEPA plenum duct connection was done.

- On 24th October, the OT Air Handling Unit was delivered and installed. Installation of OT ceiling, AGSS system, Robotic OT passage was also done along with the laying and commissioning of medical gas lines.

- On 25th October, the team completed the vinyl flooring of the OT passage and started the AC work, putty fill up and primer work.

- On 26 October, primer and paint work was started for OT wall panels. The Automatic doors were installed and our cleaning was done by an external agency.

- On 27th October, the OT wall panels were painted.

- On 28 October, the team completed the vinyl flooring of the OT. The Water Scrub Unit was installed and tested by MDD and the OT AHU chilled water, hot water, electrical panel and air duct connection was completed. Flushing and checking of the medical gas lines were also done.

- On 29th October, MDD installed the HEPA filter. Positive pressure setting was done as per the design. This was followed by terminal cleaning and HEPA filter validation by third-party vendors.

The project was completed successfully by the tremendous efforts of the team.

Gallery

Patients Speaks

Hear the heartwarming stories of patients overcoming difficult afflictions

View Map

View Map Book an Appointment

Book an Appointment Find a Doctor

Find a Doctor Health Check-up

Health Check-up

Find a Doctor

Find a Doctor Health Checkup

Health Checkup Book an Appointment

Book an Appointment